Grain dryers: Customized design

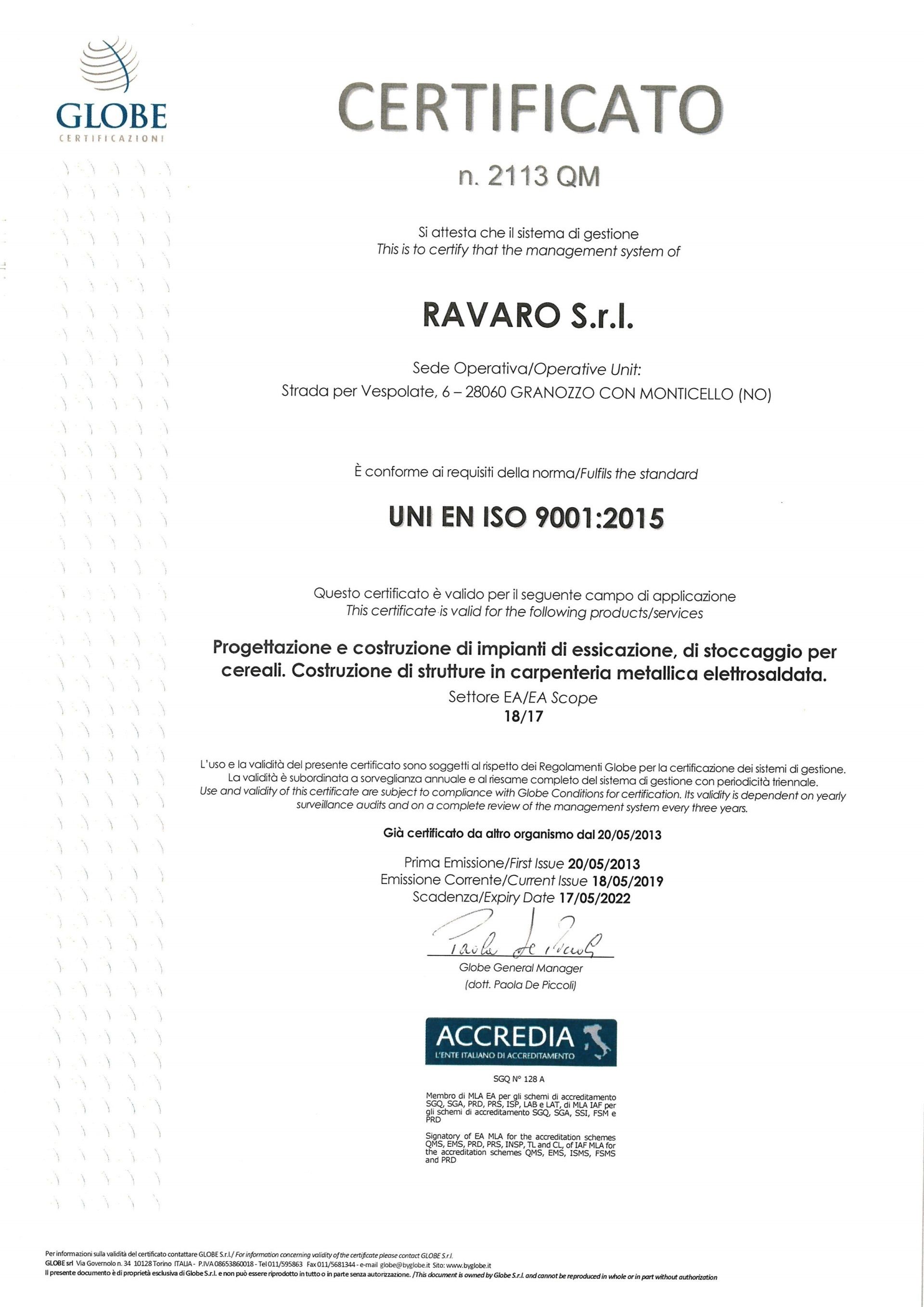

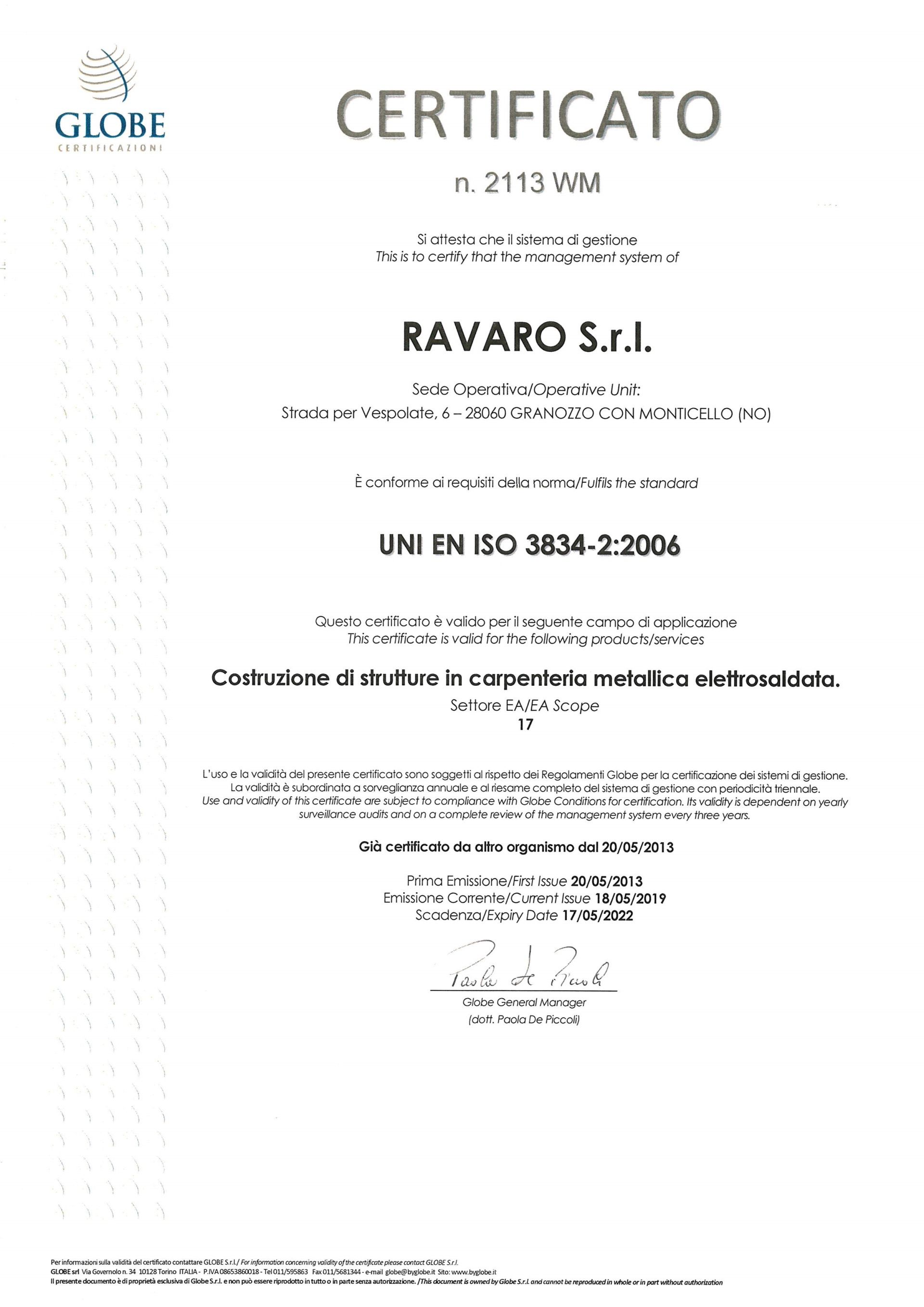

Active throughout Northern and Central Italy, in particular in regions such as Emilia Romagna, Friuli Venezia Giulia, Liguria, Lombardy, Marche, Piedmont, Trentino Alto Adige, Tuscany, Umbria and Veneto, the Ravaro Costruzioni Meccaniche company has been operating since 1967 with great professionalism in the field of design of dryers and storage for cereals

legumes. Confident that innovation is the first step towards real progress, we have therefore studied, designed and developed some new models of high efficiency dryers.

Constant commitment, development and research since 1967

Technology and innovation at the service of nature

Design and construction of storage facilities

Sale of grain dryers and cleaners

RR recycling dryerfor cereals

The Ravaro RR recycling dryer is suitable for drying all types of legume cereals, which:

- paddy;

- corn;

- soy;

- barley;

- wheat;

- rye;

- oats;

- sunflower;

- rapeseed;

- sorghum;

- pea;

- coffee.

Specialists in the design of drying systems, we at Ravaro have studied a new system for even greater performance and efficiency.

Three moments

in which the drying operation inside the RR recycling dryer is divided:

- The product descends by gravity through a series of staggered lozenges which produce a zig-zag movement and continuous mixing; the geometry of the lozenges guarantees a uniform descent over the entire section of the column, avoiding the formation of preferential currents.

- In the first drying zone the product is hit by hot air and releases most of the humidity. In the highest part of the dryer (called tempering trance) the product is not affected by any air flow (there are no lozenges, but only sheet metal boxes). In this area, the innermost humidity of the grain tends to migrate towards the outside, facilitating subsequent evaporation and improving drying homogeneity.

- Finally, during the subsequent drying phase, the residual humidity is removed to the desired final value.

Continuous RC dryerfor cereals

The continuous RC dryer developed and assembled by Ravaro, a reference company in the design of drying systems, is suitable for drying all types of legume cereals.The difference with the recycling dryer lies solely in the continuous mode: the dryer does not have a tempering phase, but is configured (number of drying tranches, product extraction speed, drying temperature, etc.) in such a way as to be able to eliminate a pre-established percentage of humidity.

The product passes only once inside the drying column and is immediately stored.

In the first sections of the machine, cooling takes place through dampers placed on the heads and dampers placed in the wind box of the dryer.

On-site consultations with technicians and designers

If you are thinking of installing a grain dryer in your company, do not hesitate to contact the specialists at design of cereal drying systems.Make an appointment with the company staff to carry out a personalized consultation and get yours immediately free quote.

Contact us by filling out the form for advice on cereal dryers

*Required fields